-

acasă

- despre noi

- produs

- fabrica de turism

- știri

-

caz

-

Contacteaza-ne

Întreținerea de rutină este minimă și include curățarea regulată, verificarea conexiunilor pneumatice și asigurarea că mașina de cusut este unsă și înfilată corespunzător. Oferim un manual complet cu programe detaliate de întreținere.

High-Performance Grain Bag Filling Machine

This grain bag filling machine offers a robust and precise solution for weighing and packaging a wide variety of granular materials. It is expertly designed for products like rice, wheat, beans, seeds, and sugar, making it a versatile asset for any agricultural or food processing operation.

The system integrates weighing, filling, automatic sewing with thread cutting, and conveying into one efficient workflow, boosting your productivity.

Weighing Range: 5 - 50 kg

Capacity: 300 - 400 bags/hour

Material: Stainless steel weighing hopper, durable carbon steel frame

Product Highlights

Exceptional Weighing Accuracy

Utilizes a high-precision controller and a three-level feeding system to achieve an accuracy grade of X(0.2), ensuring minimal product giveaway and consistent quality.

Durable & Hygienic Design

Features a large 78L single weighing hopper made from corrosion-resistant stainless steel for easy cleaning and long service life.

Intelligent and Safe Operation

Equipped with automatic error correction, fault auto-diagnosis, and an alarm for over/under tolerance, guaranteeing a stable and reliable weighing process.

Complete & Integrated System

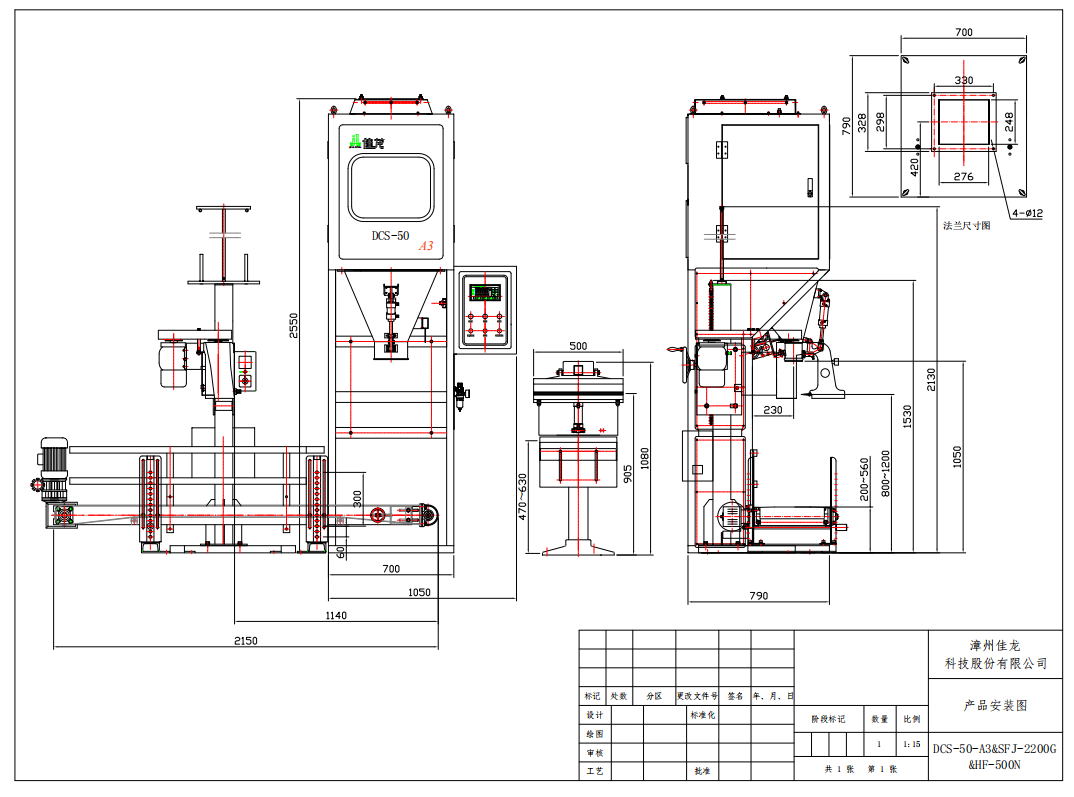

Comes as an all-in-one unit, including the packing scale body, an industrial sewing machine, and a 2.2m screw-type lifting conveyor.

Technical Specifications

| Weighing range (kg) | 5 ~ 50 |

| Speed (bag/h) | 300-400 |

| Scale interval (g) | 10 |

| Accuracy grade | X(0.2) |

| Sewing machine type | Single needle / Double thread |

| Power supply/consumption | 4N-AC 380V 50Hz 1KW |

| Air supply/ consumption | 0.4~0.6MPa 1m³/h |

| Install height (mm) | 2550 |

| Dimensions (Approx.) |  |

Application Scenarios

1

Grain Milling & Processing

Ideal for rice, wheat, and corn mills to package final products for distribution.

2

Seed & Agriculture Industry

Precisely bags valuable crop seeds and agricultural feeds with consistency.

3

Food Ingredient Packaging

Efficiently handles bulk packaging for sugar, salt, legumes, beans, and pulses.

4

Bulk Commodity Trade

Dependable solution for traders packaging granular goods for transport and sale.

Technical & Structural Advantages

Engineered for Performance and Reliability

Our machine's design is focused on efficiency. The use of a single cylinder for four-station movement creates a highly compact structure, which ensures a fast response time and significantly reduces the failure rate. Furthermore, the super filter function actively combats vibration and electrical interference, which is critical for maintaining a stable and accurate weighing process, even in busy industrial environments.

Operator-Focused Controls

Ease of use is paramount. The system is managed by a high-precision controller that is simple to operate. For maximum convenience, it includes a one-key recovery function, allowing the operator to instantly press the reset key to return to the default parameters. A reserved RS232/485 interface is also included, allowing for straightforward integration and data communication with other factory management systems.

Quality Control and Component Philosophy

Commitment to Quality Manufacturing

Every grain packing machine we produce is subject to a rigorous quality control regimen. The process starts with the inspection of all incoming materials and continues through every stage of fabrication and assembly. Before shipment, each machine is fully assembled and undergoes extensive testing with materials similar to the client's product to ensure it performs flawlessly and meets all technical specifications. Our design also emphasizes energy efficiency, consuming only 1KW of power, which helps our clients reduce their operational costs and environmental footprint.

High-Quality Component Sourcing

We build our machines to last. This is achieved by using reliable, high-quality main components sourced from internationally recognized brands. This philosophy minimizes maintenance requirements and maximizes operational uptime for our customers.

| Component | Brand/Origin | Advantage |

| Weighing controller | CN/Zhiyuanda | Stable & Precise Control |

| Switching power supply | TW/Meanwell | Reliable & Consistent Power |

| Button, Knob, electrical | France/Schneider | Durable & Safe Operation |

| Load cell | CN/ZEMIC | High-Accuracy Sensing |

| Pneumatic elements | TW/Airtac | Long Service Life |

| Air cylinder | TW/Airtac | - |

| Solenoid valve | TW/Airtac | - |

| Sewing Machine | China/Qinggong | - |

| Motor | China/hanseng/sanjing | - |

Service and Support

Pre-Sales Consultation: Our team of experts is available to discuss your specific packaging needs, material characteristics, and production goals to ensure the machine is perfectly configured for your business.

After-Sales Service: We provide comprehensive after-sales support, including a full warranty, a ready stock of essential spare parts for quick dispatch, and responsive technical assistance to resolve any issues and maintain your productivity.

Frequently Asked Questions (FAQ)

1. What types of bags can be used with this machine?

The system is designed for pre-made, open-mouth bags, such as woven polypropylene (PP) bags, paper bags, and poly-lined bags.

2. How is the machine operated? Is it fully automatic?

This is a semi-automatic machine, which offers a great balance of speed and control. The operator simply places an empty bag on the filling spout; the machine then automatically weighs the material, fills the bag, and conveys it to the sewing station for an automated stitched closure.

3. Can the packing weight be easily changed?

Yes, the target weight can be changed quickly and easily through the digital controller's user-friendly interface. The machine supports a wide weighing range from 5kg to 50kg.

4. What is included with the machine purchase?

The standard package includes the main packing scale with its hopper and controls, an industrial bag sewing machine head mounted on a column, and a 2.2-meter screw-type lifting conveyor for filled bags.

5. What kind of maintenance is required?

Routine maintenance is minimal and includes regular cleaning, checking pneumatic connections, and ensuring the sewing machine is properly oiled and threaded. We provide a full manual with detailed maintenance schedules.