-

acasă

- despre noi

- produs

- fabrica de turism

- știri

-

caz

-

Contacteaza-ne

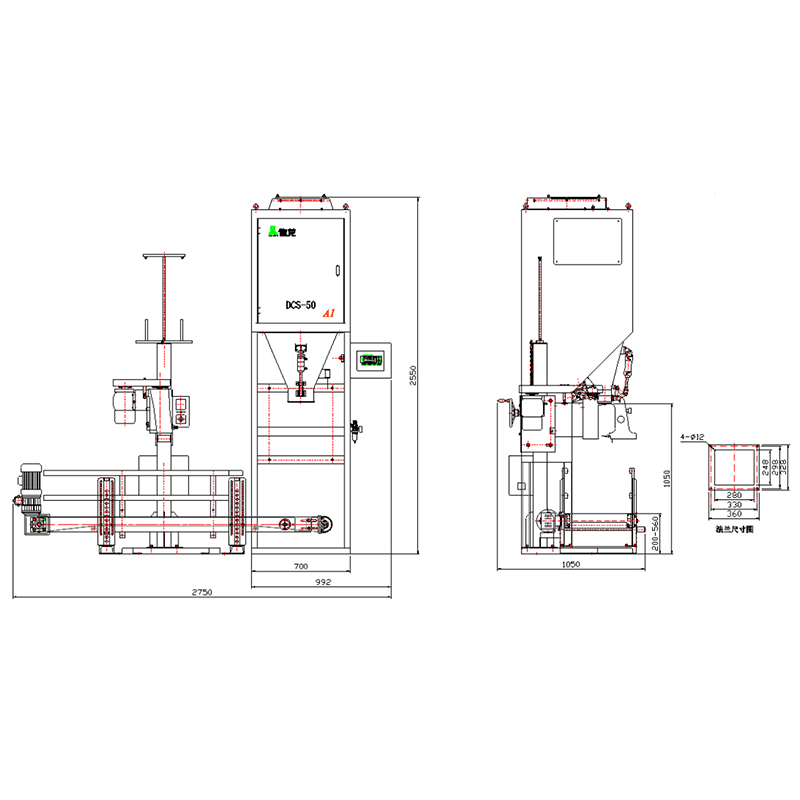

DCS-50(A1) All-in-One Semi-Automatic Bagging System

DCS-50(A1) Integrated Semi-Automatic Packing Scale

Discover an efficient, all-in-one solution for your granular packaging needs. This integrated system is expertly designed for weighing, filling, and sealing bags containing a variety of free-flowing materials.

More than just a scale, this unit includes a sewing machine and conveyor, providing a complete bagging line that streamlines your production process from start to finish. It’s the perfect entry point for automating your packaging operations.

Model: DCS-50(A1)

Capacity: 300-400 bags/hour

Material: Stainless steel for all material contact parts

Core Advantages

Complete Bagging Line

This isn't just a scale; it's a full system that includes an automatic sewing machine and a robust belt conveyor for a seamless workflow.

Reliable Precision

Features a high-precision controller with auto error correction and an anti-vibration filter to ensure stable, accurate weighing every time.

User-Centric Operation

Designed for ease of use with simple controls, automatic fault diagnosis, and a one-key function to restore default parameters instantly.

Durable & Hygienic

Constructed with a single weighing hopper and stainless steel material-contact parts, ensuring long service life and easy cleaning.

Technical Specifications

| Model | DCS-50(A1) |

| Filling Weight Range | 5 - 50 kg per bag |

| Packing Speed | 300 - 400 bags/hour |

| Accuracy Grade | Class X(0.2) |

| Scale Interval | 10 g |

| Bag Material Compatibility | Woven PP bags, paper bags, PE bags (optional) |

| System Components | Packing Scale Body, Sewing Machine, 2.2m Belt Conveyor |

| Power Supply | 4N-AC 380V, 50Hz |

| Power Consumption | 1 KW |

| Air Requirements | 0.6 MPa (constant, dry, oil-free), 1m³/h consumption |

| Installation Height | 2550 mm |

Versatile Application Scenarios

1

Grain & Agri-Food

Perfect as a 25 kg rice packing machine, and equally effective for other grains like wheat, corn, and beans.

2

Seed & Feed Industry

Provides accurate, quantitative packaging for various crop seeds, animal feed pellets, and granulated fertilizers.

3

Food Ingredient Sector

Ideal for weighing and bagging bulk ingredients like sugar, salt, pulses, and other granular food materials.

4

Chemical & Industrial

Reliably packages non-corrosive granular industrial materials such as plastic pellets, resins, or chemical salts.

In-Depth Product Details

Operational Workflow

The system streamlines the entire bagging process. An operator simply hangs an empty bag on the spout. The machine automatically weighs the precise amount of material and fills the bag. The integrated conveyor then transports the filled bag to the sewing station, where the sewing head automatically stitches the bag closed and cuts the thread. The finished, sealed bag is then ready for palletizing.

Quality Control and Manufacturing

We are committed to building robust and reliable machinery. Our manufacturing process begins with the careful selection of high-grade raw materials, including certified stainless steel and reputable electronic components. Each unit is assembled by experienced technicians who adhere to strict engineering protocols. Before leaving our facility, every machine undergoes comprehensive testing, including accuracy calibration and continuous operation checks, to ensure it performs flawlessly upon arrival.

Our Commitment to You: Service & Support

Pre-Sales Consultation: Our experts are ready to discuss your specific materials and production targets to confirm the DCS-50(A1) system is the right fit for your operation.

After-Sales Support: We offer complete installation guidance, operational training for your team, and a comprehensive machine warranty. Lifelong technical assistance is part of our commitment.

Spare Parts Availability: We maintain a full inventory of essential spare parts, including sewing machine heads, belts, and control components, to ensure minimal downtime.

System Integration: The machine's controller includes a reserved RS232/485 interface, allowing for future connectivity with data management systems or other production line equipment.

Frequently Asked Questions (FAQ)

Q1: Is this a complete packaging line or do I need to buy other parts?

A: The DCS-50(A1) is sold as an integrated system. It includes the weighing and filling scale, the automatic bag sewing machine, and the conveyor belt. It's a complete solution to get you started.

Q2: What maintenance is typically required?

A: Routine maintenance is simple and includes keeping the weighing hopper and sensors clean, checking the air supply, and periodically oiling the sewing machine as detailed in the user manual.

Q3: Can this system handle different bag sizes?

A: Yes, the machine is adjustable for different bag lengths, and the weighing controller allows you to easily change the target fill weight between 5 kg and 50 kg to suit your needs.